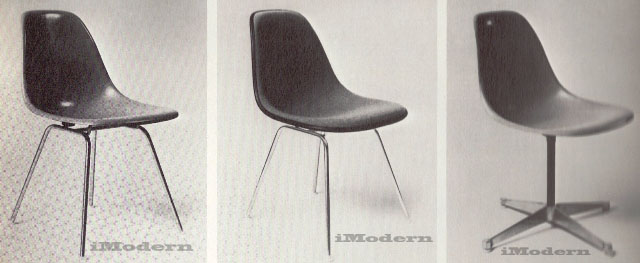

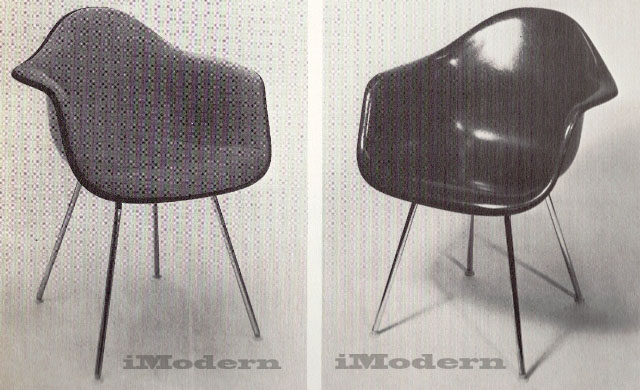

Dining chairs by Charles Eames

Eames regards the seat element as a shell that should be contoured to the human body and the leg structure as a quite distinct base, to which the shell is attached. He has evolved a whole set of interchangeable shells and supports, producing a wide range of possible permutations. Starting out first with a fibreglass reinforced plastic shell, with or without armrests, he added an armless wire mesh (now no longer in production) which could be either partially or fully upholstered. Later he made low-backed versions of these for the Fonda del Sol restaurant in New York, and also, for airport seating, a series of bases with tubular beam and cast legs.

A more recent series of designs, under the name of the Aluminium Group, uses a number of cast aluminium frame elements holding a heat-sealed pad of fabric, foam and synthetic leather in resilient tension in narrow horizontal seamed bands. This group includes low and high-backed chairs and lounge chairs, all with or without arms and all adaptable to several different swivel bases. The construction of the complete chair is particularly interesting in Eames' work, in that he has spent a great deal of effort experimenting to find satisfactory methods of joining his elements together. His most often used method of joining a seat to its base was revolutionary at its inception. It consists of a rubber casting chemically bonded to the shell with a nut embedded in it to form the connection with the base. This allows a vital degree of flexibility between the two parts. It has been pointed out by Peter Smithson that. Before Eames no chairs (of the modern canon) were many colored or really light in They use aluminium castings and wire struts which remind one (but only if one thinks about it) of new and old aeroplanes, not of other furniture. A lot of energy has been poured into their detail: it is workmanlike, explicit, even eloquent, but it is quiet'. This detail that Smithson mentions is designed to be highly appropriate to mass production techniques. All the welds Eames uses are electric resistance welds, and are not executed by hand. A resistance weld is an instantaneous process which requires no hand finishing, is elegant and structurally very sound when appropriately used. The variations possible with the seat shells, plus the range of upholstery materials, from self-colored plastic to wool fabrics, can produce chairs to suit almost any combination of function, mood and colour scheme. Even where padded covers are used, they are always a separate and removable element. Also, the bases come either chromed or black, extending a further range of alternatives. All these chairs have undergone continual modifications, additions and elaborations, to fit them for new functions: an example is the extra thick padding added to the back of the armless plastic shell when it is intended for use as a typing chair. Eames' aesthetic, both as an architect and as a designer of furniture, developed directly from a highly personal approach to functional considerations. It is unfortunate that these chairs, so carefully and successfully adapted to real mass-production, have still not achieved the recognition and the popularity that would enable them to be produced in the large numbers that would keep them at a moderate price. They are still made by the original manufacturer, Herman Miller, a very high quality company, using semi-mass production methods and selling through designers and architects to a limited luxury market. |

Site Map | Copyright 2014 | RobSequin.com | Contact Us